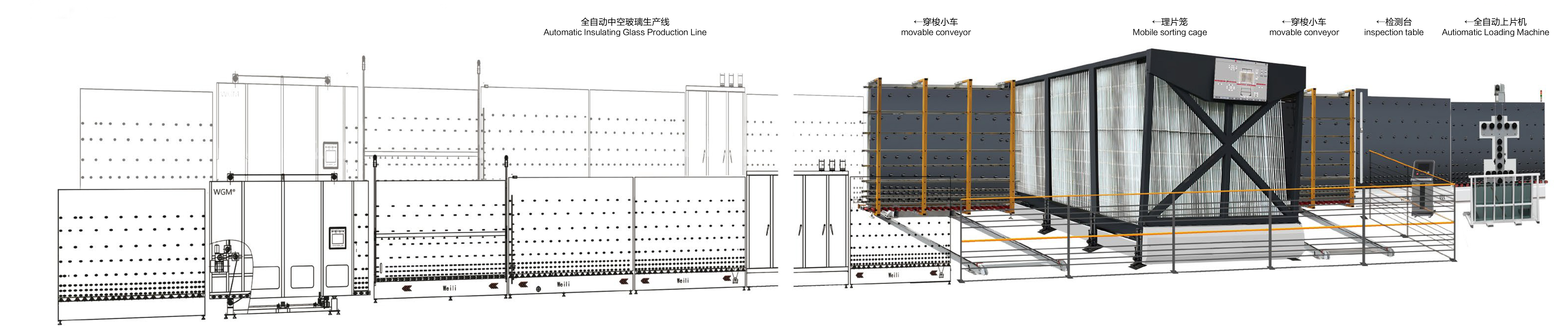

该流水线由穿梭小车、检测台、理片笼、自动立式上下片机(可选配)组成。对加工过程中的矩形玻璃进行尺寸检测后分批次储存于格栅笼,并按照系统排列次序依次取出玻璃,以此为下一道玻璃加工工序进行梳理和缓字功能;每一格栅格可储存单片或多片玻璃,从而达到存储空间的充分利用。

The assembly line is consists of movable conveyor,vertical inspection section, sorting cage and automatic vertical loading and unloading machine (optional). In the processing,first detect the rectangular glass size, store in the grating in batches, then the glass is taken out successively according to the systematic arrangement order, so as to comb and cache the next glass processing process; Each grating can store a single or multiple pieces of glass, so as to achieve the full utilization of storage space.

性能特点

(Main Feature)

1.用于中空线之前,生产效率可提高 25%-30%。

2.支持扫码功能,省去检验台环节,直接扫码确定玻璃配对信息。

3.中空玻璃加工之前对玻璃进行梳理、缓存,并达到中空玻璃加工配对需求。

1.lt is used in front of insulating glass line, the production efficiency can be increased by 25%-30%.

2.Optional: support the code scanning function, save the inspection station steps,and directly scan the code to confirm the glass pairing information.

3.Comb and cache the glass before processing the insulating glass, so as to meet the glass sorting and matching requirements.

主要技术参数(Main Techniq ue Parameter) | ||||||||||

产品型号 Product model | 电压 Power source | 最大尺寸 Max.Size | 配片节拍 Glass Matching Efficiency | 传输速度 Transmit Speed | 玻璃厚度 thickness | 倾斜角 Tilt angle | 穿梭小车速度 Movable Conveyor Speed | 笼数 Cage Qty | 设备尺寸 L×W×H Dimension mm | 功能段 Function section |

WLPL2030 | AC 380V 3ph 50HZ | 2000×3000mm | 3~4 片/min | ≤ 45m/min | 3~10mm | 88° | ≤ 200m/min | 60/Cage | 14000×6000×2620 | 6 |

WLPL2530 | AC 380V 3ph 50HZ | 2000×3000mm | 3~4 片/min | ≤ 45m/min | 3~10mm | 84° | ≤ 200m/min | 60/Cage | 14000×6000×2620 | 6 |